Introduction

In the cosmetics industry, packaging safety is crucial to ensuring that products remain safe for consumers to use and maintain their effectiveness over time. Packaging safety standards are designed to protect both the product and the end user. With the rise of stricter regulations and increased consumer awareness about safety, cosmetic brands must comply with various packaging safety standards. In this blog, we will explore the key packaging safety requirements, industry guidelines, and best practices that cosmetic brands must follow to meet safety standards and ensure that their products are safe and reliable.

1. Key Packaging Safety Standards in the Cosmetics Industry

The packaging safety of cosmetic products is governed by several international and regional regulations. These standards ensure that cosmetic packaging does not pose a risk to consumers and protects the product’s integrity throughout its life cycle.

- FDA Regulations (USA): The Food and Drug Administration (FDA) in the United States mandates that cosmetic packaging must be free from harmful chemicals and materials. For example, cosmetic packaging must be resistant to leakage and contamination. FDA regulations also require that packaging materials do not react negatively with the product inside, potentially altering its safety or efficacy.

- European Union (EU) Regulations: The EU has established comprehensive guidelines for packaging safety under the Cosmetic Products Regulation (EC) No 1223/2009. This regulation ensures that all cosmetic packaging used within the EU is non-toxic and compatible with the product. Additionally, it mandates the use of safe packaging materials that do not migrate harmful substances into the product, and it requires manufacturers to conduct safety assessments for packaging.

- International Standards (ISO): The International Organization for Standardization (ISO) sets global standards for packaging safety. ISO 22716:2007 provides guidelines for good manufacturing practices (GMP) in cosmetics, including packaging safety. It ensures that packaging materials are suitable for cosmetic use and that the packaging process adheres to strict hygiene and safety protocols.

2. Ensuring Packaging Safety Through Material Selection

The choice of packaging materials plays a critical role in maintaining packaging safety. Certain materials can be prone to contamination or degradation over time, which can compromise the product’s safety. Here are some commonly used materials in cosmetic packaging and their safety considerations:

- PET (Polyethylene Terephthalate): PET is widely used for cosmetic packaging due to its durability and resistance to chemical interactions. However, it is important to ensure that the PET used in packaging is certified as non-toxic and safe for direct contact with cosmetic products.

- Glass: Glass is a safe and eco-friendly material commonly used in luxury cosmetics packaging. It is inert, meaning it does not interact with the product inside. However, it is essential to ensure that glass containers are manufactured without sharp edges or cracks that could cause injury.

- Aluminum: Aluminum containers offer excellent protection from light and oxygen, making them ideal for certain products like sunscreens or serums. However, manufacturers need to ensure that aluminum packaging is free from harmful coatings or chemicals that may leach into the product.

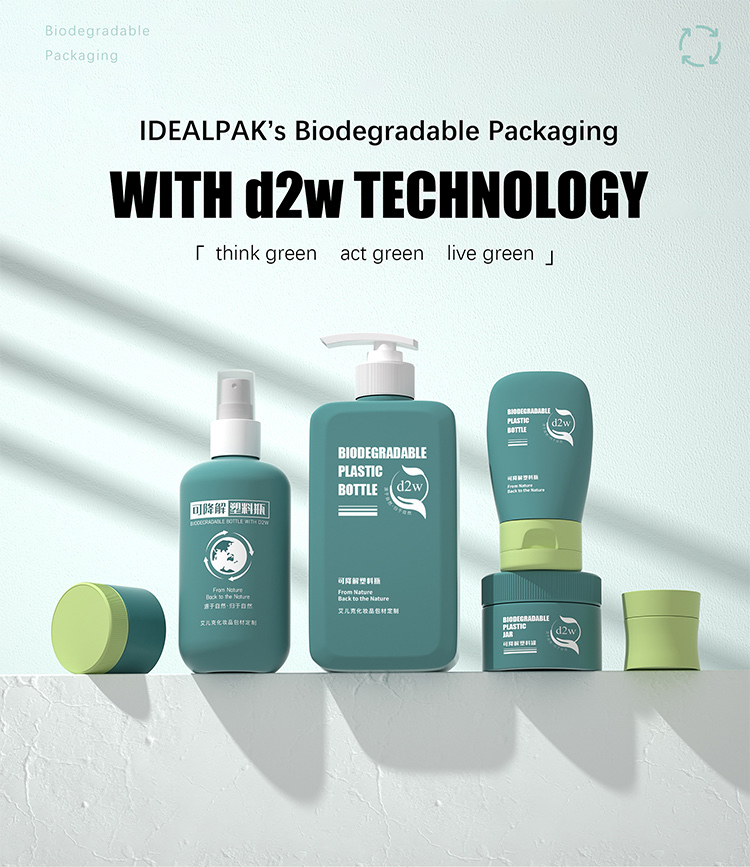

- Bioplastics: Bioplastics made from renewable resources such as sugarcane or corn are gaining popularity in the cosmetic packaging industry. They are safe and biodegradable, making them an environmentally friendly option. However, safety testing for bioplastics is still evolving, and they must meet the same safety standards as traditional plastics to ensure they do not contaminate the product.

3. The Importance of Packaging Compliance in Global Markets

Cosmetic packaging safety is not only about meeting local regulations but also about complying with international standards, particularly for brands looking to sell globally. Non-compliance with packaging safety standards can result in costly recalls, lawsuits, or brand damage. Below are some essential compliance considerations:

- Labeling Compliance: Proper labeling is a key part of cosmetic packaging compliance. Brands must ensure that packaging includes clear, accurate, and legal information, including ingredients, expiry dates, and usage instructions. Labels must also comply with local regulations, such as language requirements or warnings about allergens.

- Child-Resistant Packaging: For certain cosmetic products, such as those containing active ingredients or chemicals that could pose a risk to children, child-resistant packaging is mandatory. This ensures that the packaging is tamper-evident and difficult for children to open, ensuring consumer safety.

- Environmental Compliance: As the demand for eco-friendly packaging rises, brands must ensure their packaging materials meet sustainability standards. Packaging that is recyclable or made from recycled materials is increasingly important to meet environmental compliance and appeal to eco-conscious consumers.

4. Best Practices for Cosmetic Packaging Safety

To maximize the shelf life and safety of cosmetic products, here are a few best practices brands should follow when designing their packaging:

- Conduct Safety Assessments: Packaging safety should be evaluated regularly through safety assessments and testing. This includes ensuring that packaging does not leach chemicals into the product and does not negatively impact the formula.

- Ensure Tamper-Evident Features: Packaging should include tamper-evident features to assure consumers that the product has not been altered or contaminated.

- Focus on Product Integrity: Cosmetic packaging should be designed to protect the product from environmental factors such as moisture, air, and UV light. Packaging that preserves the product’s integrity ensures a longer shelf life and reduces waste.

5. How Cosmetic Brands Can Stay Ahead of Packaging Safety Trends

As consumer concerns around safety continue to grow, cosmetic brands must stay ahead of evolving packaging safety trends. Here are a few strategies to consider:

- Invest in Sustainable Materials: As regulations around sustainability tighten, eco-friendly packaging materials like PCR plastics and bioplastics are becoming essential. These materials must meet both safety standards and environmental requirements.

- Leverage Technology: Using technologies such as smart packaging and QR codes can improve transparency and help consumers make informed decisions about the safety of their cosmetic products.

- Regularly Update Compliance Practices: Stay informed about new packaging safety regulations by participating in industry associations and regularly reviewing local and international regulations to ensure compliance.

More content

External Links:

- FDA Packaging Safety Guidelines for Cosmetics.

- Suggested European Union Cosmetics Regulation for packaging compliance.

Internal Links:

- What Are Airless Pump Bottles? A Comprehensive Overview

- How to Choose Sustainable Cosmetic Packaging for Brands in 2024

Conclusion

Ensuring packaging safety is a critical part of the cosmetic manufacturing process. By understanding the key packaging safety standards and adhering to them, cosmetic brands can ensure the safety and effectiveness of their products while meeting consumer expectations. At IdealPak, we are committed to providing safe and sustainable packaging solutions that comply with global safety standards. Contact us today to learn how we can help you create packaging that meets the highest safety standards.