Introduction

Plastic bottles are essential in the cosmetic industry, providing not only a functional solution for storing creams, lotions, and serums but also contributing to brand identity and customer experience. However, many people wonder: How are plastic bottles made? In this article, we’ll walk you through the 10-step process of manufacturing plastic bottles specifically for cosmetic packaging, explaining each phase and its significance in ensuring the safety, durability, and aesthetics of the final product.

Step 1: Material Selection

The first step in creating a plastic bottle is choosing the right material. In the cosmetic packaging industry, the most common materials are PET (Polyethylene Terephthalate), PE (Polyethylene), and PP (Polypropylene). Each material has its own benefits:

- PET offers clarity and strength, making it ideal for shampoo or lotion bottles.

- PE is flexible and perfect for squeezable containers like facial cleansers.

- PP is often used for closures due to its chemical resistance.

Step 2: Preparing Plastic Pellets

Once the material is selected, plastic pellets (small granules of raw plastic) are prepared. These pellets are the raw form of plastic, which will later be melted and molded into the desired shape. For cosmetics, it’s essential to ensure the pellets are free from contaminants to maintain product purity.

Step 3: Injection Molding to Create Preforms

The next step involves injection molding. Plastic pellets are melted and injected into a mold to create preforms. These preforms resemble small test tubes and serve as the preliminary form of the final bottle.

- Why Preforms? Preforms are easier to transport and store before they are blow-molded into the full-sized bottles. This two-stage process ensures precision and flexibility.

Step 4: Blow Molding to Shape the Bottle

After the preform is made, it undergoes blow molding, where it is reheated and air is blown into it to create the final bottle shape. This process allows the plastic to expand and take the form of the mold.

- Cosmetic Application: For cosmetic bottles, blow molding is crucial for achieving sleek and sophisticated designs that appeal to consumers.

Step 5: Adding Bottle Necks and Closures

Once the bottle shape is formed, the next step is to create and attach the bottle neck and closure. In cosmetic packaging, closures are especially important as they help preserve the product and maintain its freshness. Common options include flip-top caps, pump dispensers, and screw caps.

Step 6: Surface Finishing and Customization

Surface finishing is an important step for creating visually appealing cosmetic bottles. Common techniques include:

- Silk Screen Printing: Used for branding and labeling, this method ensures high-quality designs that won’t fade or wear off.

- Hot Stamping: Adds a touch of luxury with metallic or shiny effects.

- Spray Coating: Offers frosted or matte finishes for a premium look.

This step helps elevate the bottle’s design, enhancing its appeal to customers while making it functional and brand-specific.

Step 7: Quality Control and Testing

Cosmetic bottles must undergo rigorous quality control tests to ensure they meet industry standards. These tests include:

- Leak Testing: Ensuring that the bottle does not leak when sealed.

- Impact Resistance: Verifying that the bottle can withstand drops or pressure during transportation.

- Compatibility Testing: Ensuring that the plastic material doesn’t react with the cosmetic formulation.

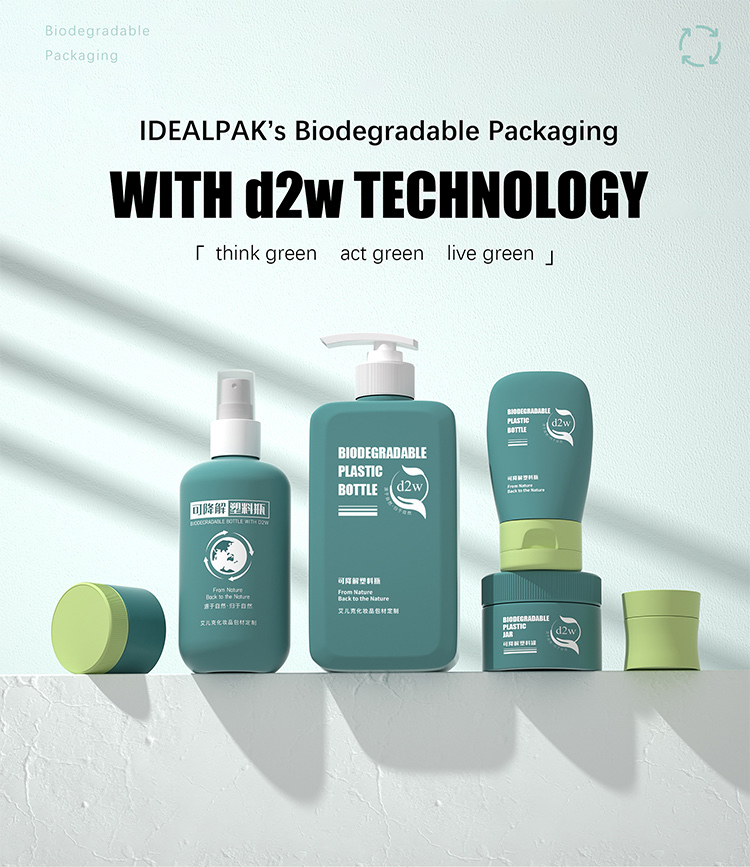

Step 8: Sustainability Considerations

Sustainability is a growing concern in the cosmetic industry, and many brands are now opting for Post-Consumer Recycled (PCR) plastic or biodegradable options. During production, some manufacturers incorporate PCR materials into the bottles, reducing the need for virgin plastic and minimizing environmental impact.

Step 9: Packaging and Labeling

After manufacturing, the bottles are packaged and labeled according to the brand’s specifications. Labels may include important information such as ingredients, usage instructions, and expiration dates. This step ensures compliance with regulations and provides transparency to consumers.

Step 10: Distribution to Cosmetic Brands

Once the bottles are complete, they are sent to cosmetic brands for filling and distribution. Whether shipped to high-end beauty brands or drugstore lines, these bottles must maintain their integrity during transportation and storage.

Conclusion: The Complexity Behind a Simple Cosmetic Bottle

The process of making plastic bottles for cosmetic packaging is intricate and involves several steps to ensure the final product is both functional and visually appealing. From selecting the right material to customizing the design and ensuring sustainability, each stage plays a key role in producing high-quality bottles that meet the needs of the cosmetic industry.

By understanding how these bottles are made, cosmetic brands can make more informed decisions about packaging materials and processes, ultimately delivering better products to their consumers.

For more information on our packaging solutions, visit our IDEALPAK website or explore our global offerings on Alibaba International Store.